Metallurgical Engineering Intern

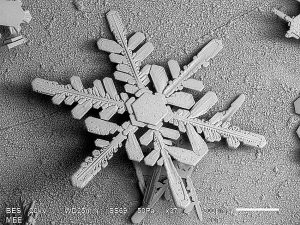

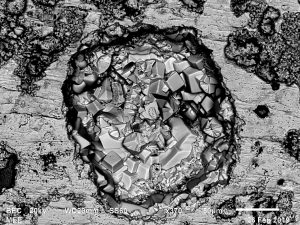

posted March 2020Welcome to MEE’s new intern, Kelsy Holtgrewe. Kelsy received her Bachelor’s in Metallurgical Engineering from Missouri University of Science and Technology in December. She’ll be starting work toward a Master’s at Colorado School of Mines this fall. She has previous work experience in the materials labs of two large industrial companies so she is familiar with many of the processes and procedures in our metallographic and SEM labs.

MEE understands that internship programs are beneficial to both the student and the company. Our busy materials science laboratories will provide Kelsy with a valuable real-world engineering experience this summer and our technical staff appreciates the opportunity to mentor new professionals in the field of metallurgical engineering.