On-site Testing and Analysis of Steel Tanks

posted August 2020

Sometimes projects involve samples or artifacts too large or too valuable to remove or cut for evaluation in MEE’s laboratories. In these cases, in situ evaluation is required.

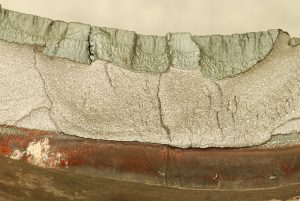

For this project, MEE was asked to evaluate the functional integrity of large steel tanks that had been exposed to elevated temperatures from a fire. Associate Engineer, Henry Ahrenholtz, is seen here preparing a field metallographic specimen. The tank surface was prepared by grinding, polishing and chemical etching to reveal the microstructure of the tank material. A replica of the prepared surface was made and then examined using a portable microscope. A Materials Engineer’s specialized knowledge of the material properties and behavior under certain environmental conditions combined with metallographic expertise in the field provided valuable information for the client to aid in assessing any damage to the tanks caused by fire.