Broad-Beam Ion Milling

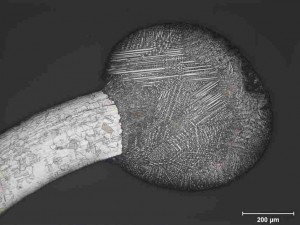

posted June 2015Senior Scientist, Dieter Scholz, spent a day at the SMTA (Surface Mount Technology Association) 2015 Midwest Expo talking with attendees about the advantages of the Broad-Beam Ion Milling. Ion Beam Milling provides an additional level of quality and clarity for critical and difficult-to-prepare samples. It is particularly useful for cross sections of semi-conductor devices, sectioning of soft materials or soft-hard material combinations or materials difficult to chemically etch.

Dieter and Larry Hanke will be presenting a paper, Microstructure Enhancement Using Ion Beam Milling, at the Microscopy and Microanalysis 2015 Meeting in Portland OR in August.

Contact us or visit our website for more information on Broad-Beam Ion Milling.

Filed under: Broad beam ion milling, microscopy, Presentations, semi-conductor devices,