Fractography and Fracture Analysis Webinar

posted July 2020Join MEE Engineers Dan Grice, P.E. and Larry Hanke P.E. next Tuesday, July 28th, for an ASM International webinar discussing the history of fractography and fracture analysis. Register today!

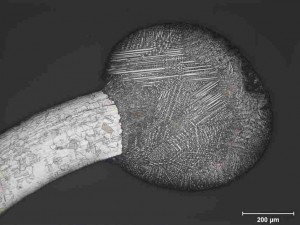

The study of fractures over the years has had an important role in materials engineering to improve product performance and reliability. This presentation will review the history of fractography, including the historical development of the science, changes in the analytical tools, and some historical case histories showing how fractography has been used over the past 100 years.