Dick Kielty

posted March 2020It is with deep sadness that we share the news that friend and past employee of MEE, Dick Kielty, passed away this week.

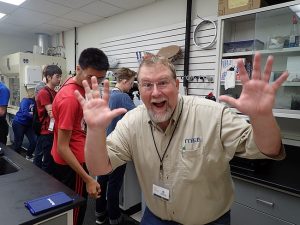

For nearly his entire career, Dick worked Twin City Testing (now Element) providing metallurgical engineering consulting services to local industries. He retired from Element but was he was not the retiring kind of engineer. Dick began working for MEE at age 73. His intent was to work part time with us for two years but two years turned into eight years and he officially retired at age 81. We so enjoyed having him around that he remained on our staff email list and would join us at staff lunches after his retirement.

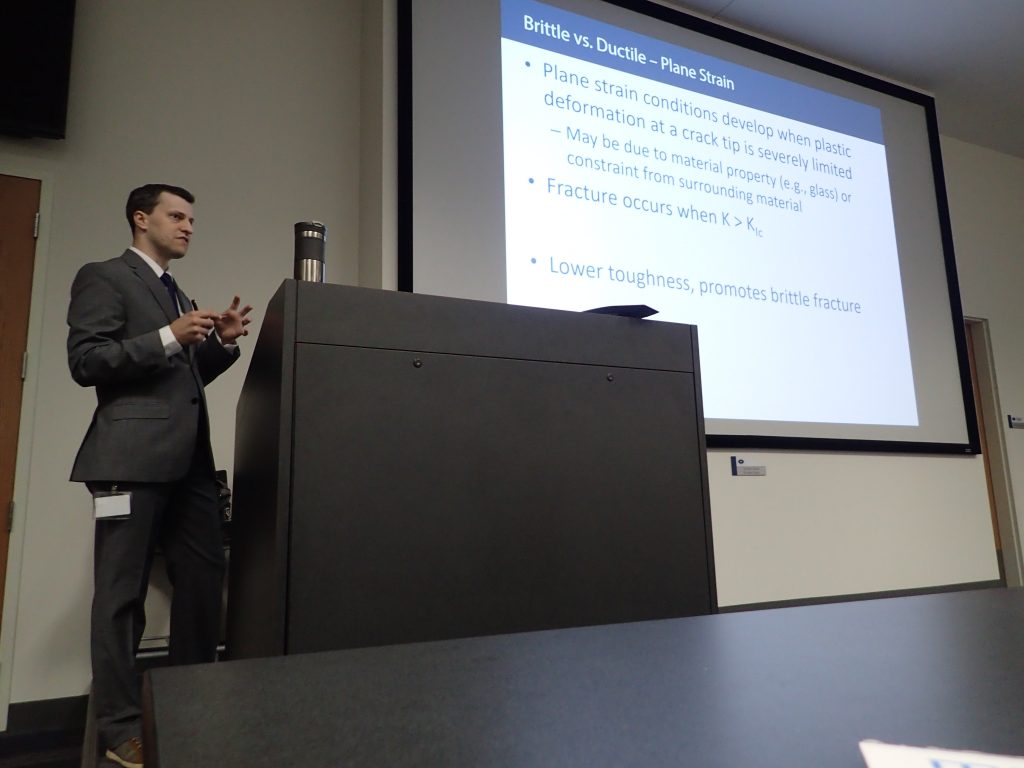

His technical expertise and years of experience were valuable assets to our team. He was a great mentor to the other engineers on staff and enjoyed sharing his knowledge whether it was done one on one or presenting staff training lectures. I think all of us in the materials science and engineering fields can agree that Dick was the role model as someone who was truly dedicated to the profession.

Filed under: About MEE, Materials Science Engineers, Materials testing laboratory,