Editor’s Choice 2020: Journal of Failure Analysis and Prevention

posted April 2021The Journal of Failure Analysis and Prevention editorial team recently announced this year’s Editor’s Choice articles, showcasing six of the high-quality articles that were published in the journal in 2020. One of these top articles was authored by former MEE intern, Reid Schur. Reid interned with us in 2016 and is currently a Materials Science PhD candidate at the University of Washington conducting research on metal additive manufacturing. Congratulations Reid.

All of the 2020 Editor’s Choice articles are free to read and can be shared with colleagues.

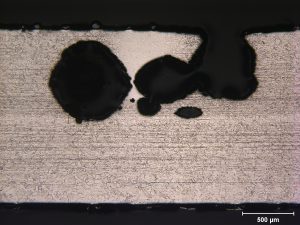

• “A Fractographic Analysis of Additively Manufactured Ti6Al4V by Electron Beam Melting: Effects of Powder Reuse” by R. Schur, S. Ghods, E. Schultz, C. Wisdom, R. Pahuja, A. Montelione, D. Arola, and M. Ramulu, Vol 20(3), June 2020, p 794-803 https://link.springer.com/article/10.1007/s11668-020-00875-0

• “Effects of Axial and Multiaxial Variable Amplitude Loading Conditions on the Fatigue Life Assessment of Automotive Steering Knuckle” by K. Reza Kashyzadeh, Vol 20(2), April 2020, p 455-463 https://link.springer.com/article/10.1007/s11668-020-00841-w

• “UV Aging Effects on Polycarbonate Properties” by S. Redjala, N. Aït Hocine, R. Ferhoum, M. Gratton, N. Poirot, and S. Azem, Vol 20(6), December 2020, p 1907-1916 https://link.springer.com/article/10.1007/s11668-020-01002-9

• “Failure Analysis of an Ambulance Cathode Ray Tube Monitor Bracket” by Eli Vandersluis, Alan Machin, Doug Perovic, and Comondore Ravindran, Vol 20(1), February 2020, p 23-33 https://link.springer.com/article/10.1007/s11668-020-00804-1

• “Failure Investigation of a Blast Furnace Top Gas Recovery Turbine: Chronology and Mechanism” by Kaushal Kishore, Susovan Das, Himangshu Mandal, Omji Anand, Goutam Mukhopadhyay, Manashi Adhikary, and Anup Kumar, Vol 20(4), August 2020, p 1376-1387 https://link.springer.com/article/10.1007/s11668-020-00951-5

• “Investigation on the Crack and Thinning Behavior of Aluminum Alloy 5052 Sheet in Stretch Flanging Process” by Surendra Kumar, M. Ahmed, and S. K. Panthi, Vol 20(4), August 2020, p 1212-1228 https://link.springer.com/article/10.1007/s11668-020-00922-w

Filed under: ASM, Failure Analysis, Materials Science Engineers, Materials testing laboratory,