Mentoring Materials Science Students

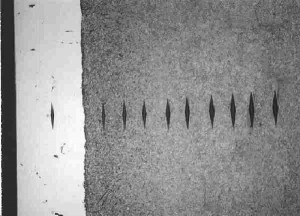

posted June 2018Last Thursday we hosted thirty high school students at MEE as part of a week-long Materials Science Camp sponsored by the MN Chapter of ASM International. Under the direction of industry and academic based “Materials Mentors”, students learned about the process of running a failure analysis investigation. MEE provided a space for the students to get hands on experience with sample preparation, Rockwell hardness testing, light microscopy and scanning electron microscopy.

Three of our staff, Larry Hanke, Kurt Schenk and Neal Hanke, were camp mentors. This was MEE’s twelfth year sponsoring the camp.