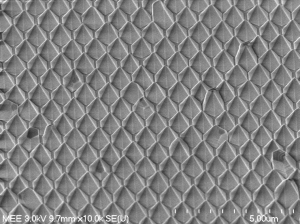

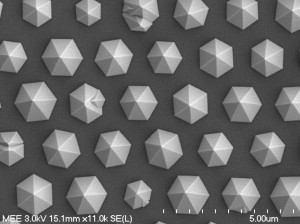

Newest Microscope adds to MEE Capabilities

posted November 2019Senior Engineer, Dan Grice is seen here completing the installation of the newest microscope in our inspection lab, a Keyence 7000 series digital light microscope. This is the world’s first 4K ultra-high accuracy microscope. Compared to our current model the expanded features of the 7000 series include 20x greater depth of field, measurement tools allowing measurements directly on screen, 3D display to observe surface contours, adaptive lighting and multi-angle observation. The increased speed and resolution of this microscope will be especially beneficial when we facilitate large joint inspections in our lab.

Filed under: About MEE, Materials testing laboratory, microscopy,