Two types of modern scanning electron microscopes provide the range of sampling handling and resolution needed for evaluating most samples – the variable pressure SEM (VPSEM) and the high-resolution field emission SEM (FESEM). At MEE, we offer SEM services with both types of microscopes to meet almost every challenge.

The VPSEM is a workhorse for routine work, but magnification is not adequate for observing the smallest features that we often need to see. With a much brighter electron source and smaller beam size, the FESEM increases the useful magnification range for observation and imaging up to 500,000X.

MEE is one of the few independent materials characterization labs in the Upper Midwest offering both variable pressure and field emission scanning electron microscopy.

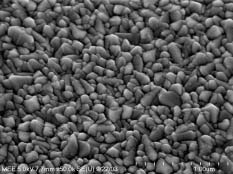

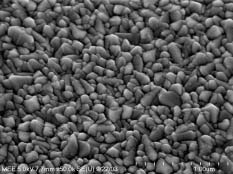

These images provide a comparison of VPSEM and FESEM operating under similar conditions on the same thin film sample.

Variable Pressure Scanning Electron Microscope 34000X

Field Emission Scanning Electron Microscope 34000X