Fractured Glass Cooking Pot Lid

A glass lid for a cooking pot cracked spontaneously during hand washing. The lid was about 8 inches in diameter and consisted of tempered glass with stainless steel rim and a stainless steel handle. The glass portion of the lid cracked into many small pieces typical of a tempered glass fracture, but all the pieces were held in place by the stainless steel rim. The lid had not been dropped, nor had other objects impacted the glass.

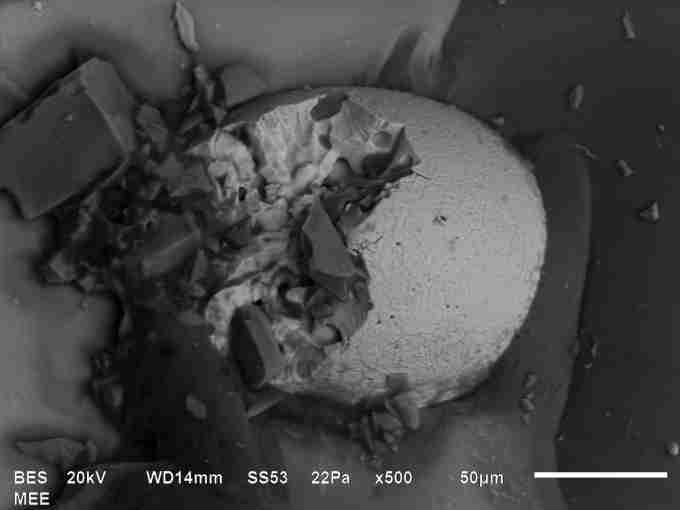

The glass fracture pattern consisted of a high density of cracks radiating from a single location about 1.5 inches from the lid center, which indicated that this location was the fracture origin. The glass pieces at the fracture origin were removed and inspected by light microscopy and scanning electron microscopy (SEM). Elemental analyses were performed by energy dispersive x-ray spectroscopy (EDS).

The morphology for the fracture faces indicated that the fracture originated at a spherical inclusion, located about 30% into the glass thickness. By SEM, the inclusion was very bright compared to the surrounding glass. The inclusion was about 0.1mm across. EDS analysis of the typical glass material detected silicon, oxygen, sodium, calcium, and magnesium. This composition is characteristic of a common soda-lime float glass. EDS analysis for the inclusion detected high concentrations of nickel and sulfur. The shape, size, and chemistry for the inclusion were consistent with nickel sulfide.

Nickel sulfide inclusions (commonly referred to as nickel sulfide stone) in tempered glass are known to cause spontaneous fracture such as what occurred for the tempered glass lid. The influence of the nickel sulfide inclusion on the fracture properties for the glass is dependant on the size of the inclusion, the position within the thickness of the glass, and the location on the overall piece of glass.

Nickel sulfide is an impurity that can occur in the glass manufacturing process. This compound exists in different phases at different temperatures. At temperatures above 379°C, nickel sulfide is stable in a an alpha phase. Below 379°C, it is stable as a beta phase. The beta phase is greater in volume than the alpha phase by 2 to 4%. During the tempering process, the glass is heated to above 600°C (where nickel sulfide is in the alpha phase) and then “quenched”, i.e., rapidly cooled. The rapid cooling does not allow sufficient time for the nickel sulfide to completely transform from the alpha to the beta phase. The inclusion therefore is constrained in the glass in the high-temperature alpha-phase. Over time the nickel sulfide continues to slowly transform from alpha to beta, and the trapped stone increases in volume. This expansion of the nickel sulfide creates localized stresses on the glass. The stresses produce microcracks within the glass that eventually lead to a complete spontaneous fracture.

In conclusion, the root cause of the failure was the presence of a nickel sulfide inclusion within the glass causing localized stress as it transformed from alpha phase to beta phase.

The work scope for this analysis consisted of light microscopy, scanning electron microscopy (SEM), and energy dispersive x-ray spectroscopy (EDS). For specific details on these methods, please see the Handbook of Analytical Methods of Materials on our website or contact us for more information.